Electrical sensing methods for particle size analysis

Electrical methods for particle size analysis include resistive pulse sensing or RPS, and its microfluidic cousin, microfluidic resistive pulse sensing, or MRPS. These both use electrical signaling to measure particles suspended in fluid one at a time, as the particles pass through a pore between two fluid-filled volumes. Spectradyne’s MRPS technology uses microfluidic resistive pulse sensing implemented using a disposable microfluidic cartridge to provide unparalleled accuracy in particle size and concentration. In our ARC Particle Analyzer, we combine the power of our MRPS technology with single-particle fluorescence (F-MRPS) to give accurate particle size and concentration measurements while also gathering fluorescence data to characterize sample attributes such as payload and phenotype.

Spectradyne’s F-MRPS Technology

Spectradyne’s ARCTM utilizes our powerful MRPS technology along with simultaneous single-particle fluorescence to provide new insights into your science. By focusing a laser on the nanoconstriction where the MRPS measurement takes place, we can collect a particle’s emitted light and derive single-particle fluorescence data. We then use various dichroic filters to partition the emitted light into specific wavelength ranges to separate the data from each fluorophore in the sample, such as FITC and CD81 or PE and PerCP, simultaneously. These dichroic filters can be easily exchanged to accommodate a wide range of different fluorochromes depending on the sample, and can also be configured to allow up to three different emission bands to be measured simultaneously. Our groundbreaking F-MRPS technology allows for deep insights into your sample’s particle size distribution, concentration, payload, encapsulation efficiency, and much more!

Spectradyne’s MRPS Technology

Microfluidic resistive pulse sensing (MRPS) is the microfluidic cousin of resistive pulse sensing or RPS. The main difference is that the analysis chamber in RPS is replaced by a disposable microfluidic cartridge, where different cartridge models are designed to have different size apertures, allowing a wider range of particle sizes to be analyzed. This means that the cartridge chosen for the particle size analysis can be optimized for the particle sizes expected in the sample.

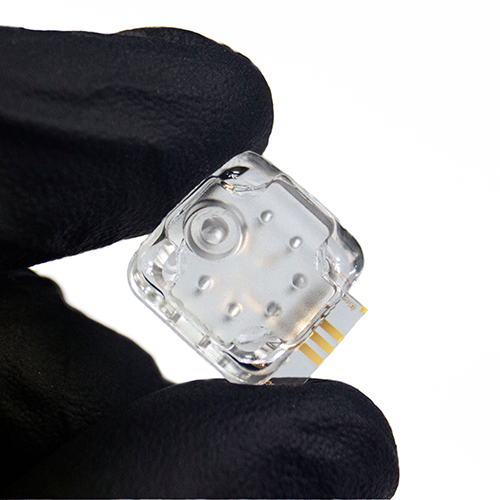

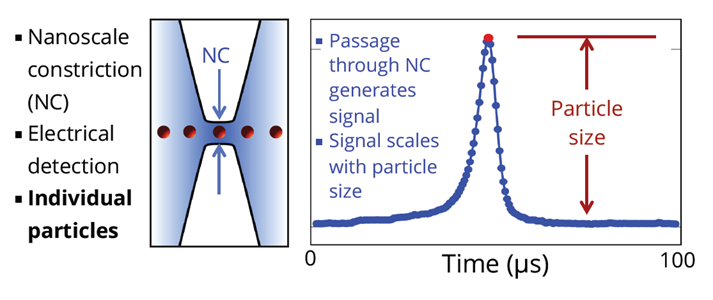

Spectradyne’s nCS1TM and ARCTM employ microfluidic resistive pulse sensing using disposable microfluidic cartridges. By using state-of-the art microfluidic fabrication technology, we have shrunk the critical particle sensing constriction used in traditional RPS by a factor of 100 or so, from a few tens of microns in diameter to a few hundred nanometers. This allows us to detect much smaller particles using MRPS than is possible using RPS. A schematic of a microfluidic cartridge is shown below. The microfluidic cartridges include a 3 μL reservoir for the analyte, on-board filters, ports for voltage-biasing the analyte, a sense electrode, a fluid resistor and the critical MRPS aperture or nanoconstriction, through which particles flow one at a time. The analyte, which could be blood serum, diluted or full-strength phosphate-buffered saline, or any conducting fluid, is electrically biased by the voltage-bias electrodes, causing an electrical current to flow through the analyte, the fluidic resistor and the aperture. When a particle suspended in analyte flows through the aperture, it changes the electrical resistance of the constriction by occluding part of the current, by an amount proportional to the ratio of the nanoparticle volume to that of the aperture, just as in RPS. Individual particles thus give changes in the sense voltage proportional to their volume, allowing them to be counted and sized. The much smaller apertures available in Spectradyne’s microfluidic cartridges allow much smaller particles to be detected.

The disposable MRPS cartridge includes ports for voltage bias Va and Vb, a microfluidic nanoconstriction or aperture Ra and a fluidic resistor Rb, The voltage bias causes a current I to flow, setting the voltage Vout of the sense electrode. Particles flowing through the aperture change the aperture resistance in time (top right), thereby causing measurable changes in the sense voltage Vout. These changes are proportional to particle volume, so each particle’s volume is measured individually.

Want to learn more?

Click here to view a webinar on our technology.

We discuss the technology behind the nCS1 and ARC and present detailed measurement results.

You can read more about microfluidic resistive pulse sensing elsewhere on our website:

- An overview of our technology

- Compare with the other particle size analyzer technologies

- Spectradyne’s MRPS allows measurements over a wide range of concentrations

- Specifications for Spectradyne’s nCS1TM

- An article published in American Laboratory is available here

- A technical article that appeared in Nature Nanotechnology is available here

The microfluidic cartridge at the heart of our MRPS technology.

Spectradyne’s nCS1TM, which performs measurements using a microfluidic cartridges.

Spectradyne’s ARCTM, combining fluorescence detection and MRPS.

The path to MRPS – Resistive pulse sensing (RPS)

Resistive pulse sensing (RPS) is the particle size analysis method used worldwide to quantify red and white blood cell counts in whole blood analysis, where it is also known as Coulter counting. The method relies on the electrical sensing of the size of particles. A sample volume is separated into two sides by an impermeable membrane in which a small opening has been made. Both sides of the volume are filled with a weakly electrically-conducting fluid (such as saline or other biologically-compatible solution); one side of the volume also has the particles to be analyzed. A small pressure difference is applied across the aperture, causing fluid, and the particles suspended in it, to pass through the aperture. An electrical voltage bias is simultaneously applied across the aperture, causing a small electrical current to pass through the aperture. When no particle is passing through the aperture, the electrical current has one value; when a particle passes through the aperture, it changes the volume through which the electrical current can flow, so the electrical resistance of the aperture increases. The electrical current is correspondingly reduced, by an amount that turns out to be strictly proportional to the volume of the particle.

RPS is thus a single particle method: Each particle that passes through the aperture momentarily changes the electrical current by an amount proportional to the particle volume, for a time inversely proportional to the speed of the particle, and thus the flow rate of the fluid. By counting particles and measuring the flow rate, the particle concentration can be very accurately determined; by binning the volumes of the particles as they pass through, a quantitative analysis of the number of particles as a function of particle volume can be calculated.

These data form the basic output for a particle size analysis performed by RPS: Particle concentration versus particle size. As each particle is sensed individually, there are no assumptions about how the signal that is detected is related to the number or size of each particle: The measurements are direct. RPS instruments are benchtop instruments, and sample preparation is minimal. The size range of particles that can be analyzed using RPS depends on the size of the aperture and the sensitivity of the electronics used to detect the particles; typically the dynamic range (in terms of particle diameter) is from about 1 μm up to 100 μm. In standard RPS, the two volumes containing the fluid, and the aperture that connects them, is a permanent part of the instrument, and is not normally disposable; this thus allows for some sample cross-contamination. However, in microfluidic RPS (MPRPS), which we discuss below, this central particle analysis part of the instrument is replaced by a disposable microfluidic cartridge, eliminating this potential source of error.

Particles in fluid pass through a constriction (NC) as shown on left side of the drawing above. A voltage is applied continuously across the two sides of the NC. As particles pass through the NC, the output signal changes in proportion to the volume of the particle. Particles are measured individually, with no dependence on particle material.

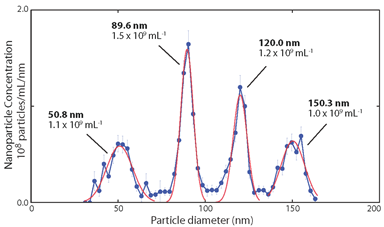

Typical data achievable using a RPS instrument for particle size analysis, with quantitative vertical and horizontal axes accumulated from single particle measurements, with good particle size resolution.