Field flow fractionation

Field fractionation techniques separate particles suspended in a fluid sample using what is called a "field," where under the action of the field, different particles move at different rates. The field used for the separation depends on the particular instrument; it can be a gravitational field, a centrifugal field, a thermal gradient, a magnetic force, and so on.

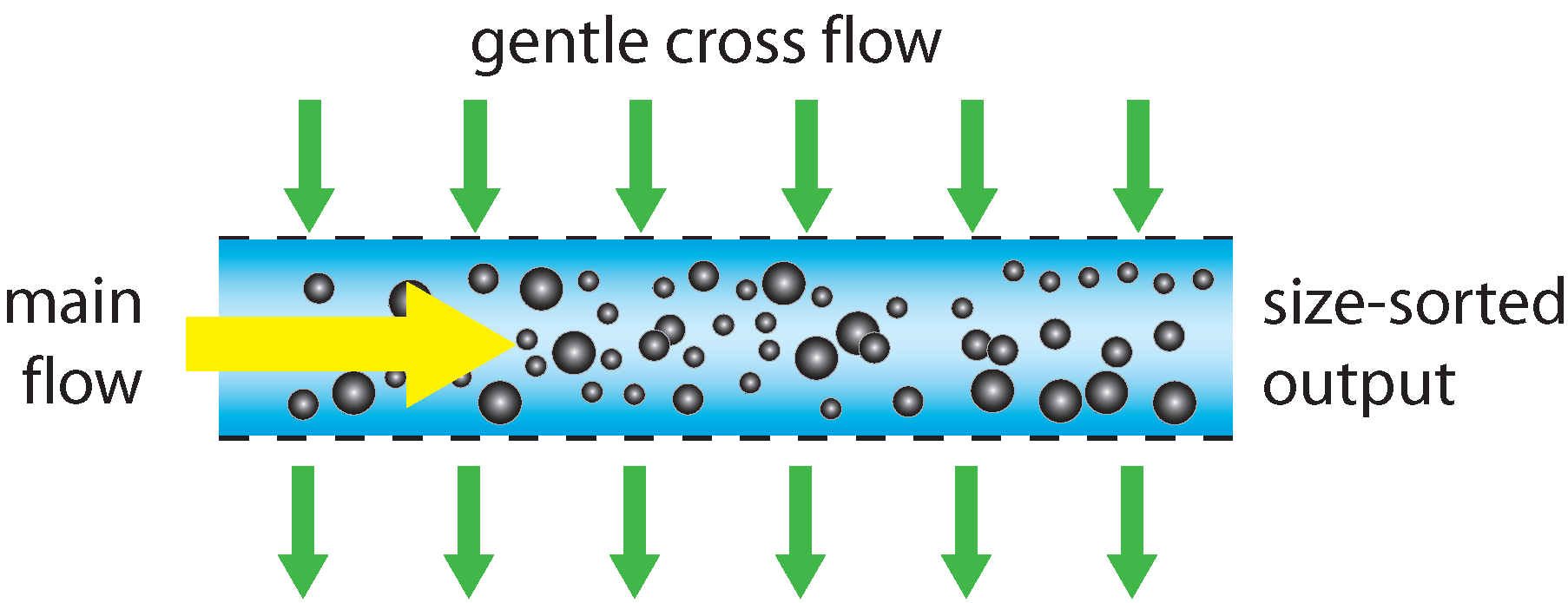

Field flow fractionation (FFF) provides the best known method for field fractionation. Fluid containing the particles to be analyzed is flowed through a long channel whose sides are formed by semi-permeable membranes. A gentle perpendicular fluid flow is passed through these membranes, causing a slow drift in the particles moving along the channel, where larger particles move slightly faster in this cross-flow than smaller particles, due to their larger hydrodynamic radius and thus larger drag coefficient. At the output of the channel, there is as a result a gradient of particle sizes across the width of the channel, and this gradient is detected, typically using an optical imaging method, which measures the relative concentration of different diameters across the channel width. This is not a single particle-by-particle method, as it measures a bulk response. Quantitative concentration measurements are difficult, but proportional particle number versus hydrodynamic radius information can be extracted.

The method requires little sample preparation and the instrument is a bench-top instrument. Cross-contamination of samples can occur as the analysis volume is not disposable. It is not a single particle method, so suffers from the usual challenges, yielding more proportional than absolute particle size and concentration information. It works for a wide range of particle sizes, which can be separated with diameter differences as small as 10%. However it can be confounded by the parabolic Poiseuille flow pattern in the main channel, where particles near the boundary flow more slowly and can accumulate on the downstream side of the separating flow, while on the opposite, upstream, side the particles cross into the higher flow rate near the center so separate by a different amount from particles that start in the channel center.

Schematic operation of a field-flow fractionation sorter.