Topics for our FAQs

Sample-related FAQs

Q: How can I get samples tested for free?

Spectradyne would be happy to demonstrate the power of its technology by measuring a few of your samples for free. Get in touch with us by filling out the contact form here, and choosing "Request Sample Measurements" from the dropdown menu. We'll be in touch shortly after you submit the form.

Q: How do I use control beads in my sample?

The quick answer is — lots of ways! The main point is to add, or spike, particles of a known size and concentration into the sample you want to measure. With MRPS, particles are measured one by one and independently from one another, so the control particles provide an in-measurement reference for absolute size and concentration-validation on the spot. Learn more about this technique by reading our blog post on the topic!

Q: How do I measure viral titer by MRPS?

Just like any other type of nanoparticle! Spectradyne's customers have used the nCS1 to measure a broad range of virus types, including lentivirus, adenovirus, flu and HIV. Check out our virus applications page, watch a webinar, or read one of these blog entries to learn more: Rapid Viral Titer with Spectradyne's nCS1, or Fascinating Virus Measurements with Spectradyne's nCS1.

Q: What is the minimum conductivity I can use for my sample solution?

We recommend for best results the use of unit strength PBS (phosphate buffered saline). For any buffer that is significantly different than PBS, the best practice is to measure a standard particle size in the proposed buffer (most easily spiked directly into the sample, or otherwise in a separate measurement) to obtain the calibration scaling factors for that type of sample (which can be saved for future use). We have successfully made measurements in buffers as dilute as 0.01x PBS; the size calibrations change somewhat, and the noise floor increases, but our instrument works quite well.

Q: What is the maximum conductivity I can use for my sample solution?

There is no maximum conductivity when using the nCS1TM. However, note that while increased conductivity does increase sensitivity, it may also increase baseline noise. Also, if the conductivity is sufficiently higher than 16 mS/cm (similar to 1× PBS), you may want to create and store a separate set of calibration values for that buffer (see the FAQ below, measuring particles with unknown conductivity).

Q: What is the concentration of particles in my sample?

Many particle standards are sold with only limited information about the particle size distribution — often only an estimate of mean diameter and the weight percent of stock material solids in solution. To convert these values into an estimate of concentration in particles/mL, visit our convenient online calculator. This calculation provides only a ballpark estimate of number concentration though, because the actual concentration over any size range depends on the detailed particle size distribution in the sample. To obtain an accurate measurement of the particle concentration, you will of course need an nCS1, which you can request here.

Q: Do I have to add Tween to my sample solution?

Tween (also known as polysorbate-20) is our default wetting agent when additional surfactant is required, with typical concentrations of 0.1% to 1%, depending on the sample. Bovine serum albumin (BSA) at 0.1% and sodium dodecyl sulfate (SDS) at 0.5 mM are alternate surfactants to consider when Tween, for whatever reason, won't work for you. Your sample might already have natural surfactants in the form of proteins and exosomes, which can eliminate the need for additional wetting agents.

Q: How can I measure samples with little or no surfactant?

For large-size cartridge measurements (i.e. when using the TS/C-900, TS/C-2000, or TS/C-10k cartridges — see our cartridge map), additional surfactant is not necessary. Cartridge wettability however becomes critical for smaller-size cartridges. For best results, we recommend preparing the samples with a surfactant such as Tween (polysorbate-20) at 0.1% to 1% or BSA at 0.1%, filtered to 20 nm to reduce the contribution of background particles.

Q: What is the best practice to generate a successful measurement method?

To ensure a successful measurement, first make sure the sample fluid has enough conductivity and sufficient surfactant to wet out the cartridge. Spike in a known particle size standard for positive control. Choose a size that won't interfere with the sample particle distribution and is at least 10% below the maximum cartridge size limit. Target a control particle concentration that is approximately 10-fold greater than the expected particle concentration in the sample at the control particle size. Prepare control particles in the same or similar diluent as the sample buffer. Dilute the sample to get the particle concentration to be within the concentration range limit of the cartridge.

Q: I don't know what's in my sample. What's the best method to measure it successfully?

To successfully measure your sample, you should start by adding control particles to the sample until a method has been developed. Measure in the largest-size cartridge first (i.e. a TS/C-2000 or TS/C-900 cartridge — see our

cartridge map) to check for the presence of large particles that could overwhelm a smaller size cartridge's internal filter or measurement channel.

In our experience, significant filter blockage can occur if the total amount of particles with diameters above the maximum size limit for a cartridge class is greater than 1×107 particles/mL. In this case, try diluting or filtering the sample to reduce the concentration of large particles.

Q: How can I measure particles in a buffer with unknown conductivity?

If a buffer has an unknown conductivity, then it is usually best to start by measuring some NIST-traceable size standards in the unknown buffer. The factory default size and concentration scaling factors for each cartridge mold are based upon the conductivity of 1× PBS (conductivity of 16 mS/cm), so if the buffer being used has unknown conductivity, one may need to develop scaling factors specific to that buffer.

The procedure to do this is quite simple: First spike in beads of known size and concentration into the target buffer, then measure with the nCS1TM. The resulting data is loaded into the nCS1 ViewerTM software, where it is corrected to show the proper size and concentration for the known beads, which creates size and concentration scaling factors specific to the unknown buffer. These values are saved as a unique calibration for that particular buffer. In the future, any time a sample is measured in that buffer, one merely loads the stored calibration for the buffer used, and the data is automatically corrected for the conductivity of that specific buffer.

Q: How can I figure out the concentration of my bead standards?

Particle standards often come with only limited information about the particle size distribution. To convert from percent solids and a mean diameter to an estimate of concentration in units of particles per ml, use the handy calculator we've provided on our website.

*Disclaimer: Since the actual concentration of particles over any size range depends on the detailed particle size distribution, the most accurate results are obtained by directly measuring the absolute concentration of particles in your sample using Spectradyne's nCS1!

Q: How much of my sample is actually measured, and how can I be sure the results are representative of the whole sample?

In all particle analysis measurements, one must start with the assumption that the sample particles are uniformly distributed in the media being measured. If the sample is being taken from a large supply, then one should adhere to well-established statistical sampling protocols developed by standards organizations such as ISO-11648 and many others, which are well beyond the scope of this FAQ.

While the nCS1TM instructions call for using 3 μL of sample in the cartridge, the actual amount measured is significantly smaller. Essentially, the system "sips" the sample through the nanoconstriction while the bulk goes straight to waste. As one goes to smaller size nanoconstrictions (NCs), the flow rate gets smaller, so less sample actually goes through the NC during the same unit time as would go through a larger NC. The key thing to remember is that the system measures the actual amount of sample that has gone through the NC on a particle-by-particle basis; it is not an estimate! This is why the nCS1TM consistently gives more accurate concentration measurements compared to competing technologies. The actual total amount of sample measured in any given run is recorded and stored as user-accessible metadata with the individual run.

Q: There's polysorbate in the running buffer-do I need to worry about compatibility with my sample?

The running buffer does not come into contact with the sample until after detection; there is no need to worry about compatibility issues.

Q: How much sample volume is required?

To perform a complete measurement with the nCS1TM, only 3 to 5 μL of sample volume are required, except when using a TS/C-10k size cartridge, in which case 10 μL are needed. To learn more about cartridge sizes, please check out our cartridge map page.

Instrument-related FAQs

Q: How can I order cartridges?

We look forward to fulfilling your order! Start by requesting a quote here.

Q: Why is there a minimum and maximum particle concentration for each cartridge type?

In general, one should use the nCS1TM cartridge map as a guideline. The maximum concentration has been determined experimentally using monodisperse calibrated spheres, and therefore should only serve as a guideline. Samples with continuous particle size distributions may behave differently than a monodisperse bead population. If the sample concentration (particles/mL) is known, then it is suggested to start by diluting to approximately 2 orders of magnitude lower than the maximum shown on the chart. For example, if using a TS/C-400 cartridge, we recommend shooting for 1x109 particles/mL to start, based on the 1×1011 particles/mL maximum shown on the chart. If the concentration of the sample is unknown to start, it is recommended to start very dilute, and then work your way up to find the optimum concentration/dilution.

The minimum concentration shown on the cartridge map is only a guideline. Since the number of particles measured is a function of concentration and flow rate, the numbers shown on the chart are based on being able to measure ~500 particles in 10 minutes of acquisition. It is possible to measure lower concentrations if you are willing to measure over a longer period of time and/or settle for a smaller number of particles measured. With 10 μL of analyte pipetted into the cartridge, measurements taking over an hour are possible (dependent on cartridge size; larger size nanoconstrictions have higher flow rates, therefore the sample does not last as long as cartridges with smaller nanoconstrictions).

Q: Where is the peak I see in my NTA/DLS data but not in my nCS1TM measurements?

In DLS (dynamic light scattering) measurements, the DLS instrument always produces a "peak", even when the

actual particle distribution has no peak! DLS is an ensemble method: it only measures the mean particle size for the entire sample along with an estimate of the polydispersity (polydispersity index or PDI). The graphs produce by DLS are not true particle size distributions like those produced by the nCS1TM, so the "peaks" they show are not real.

In NTA (nanoparticle tracking analysis) measurements, one may also often see a "peak" in samples where the nCS1TM measurement does not show one. This is a complex subject, and we invite you to read the many documents we have published on it (check out this technical brief, or this poster, or alternatively this poster). The bottom line is that any light-scattering technique is heavily biased toward large particles due to the 6th order relationship of diameter to light scatter. In NTA, this means that in a polydisperse sample, the larger particles scatter so much that they obscure the signal from the smaller particles, leading to a drop in measured concentration for the smaller particles which in turn creates a "false peak" in the lower size ranges.

Q: I loaded my cartridge but the blue light on the front panel didn't come on. What should I do?

If you load a cartridge and the blue light doesn't come on, please refer to the illustration on the Key Reminders card on the front of the instrument. Make sure that the cartridge is loaded correctly, with the front edge and back edge of the glass captured as indicated on the card, and that the cartridge is sitting flat on the bottom of the holder. If the blue light still doesn't come on, contact us at support@spectradynellc.com.

Q: When should I use my cleaning cartridge?

The cleaning cartridge should only be used during instrument start-up to prime the instrument before the first sample measurement and again when shutting down the instrument. There is no need to use a cleaning cartridge in between each sample.

Q: I can't get my cartridge to fill with analyte. What should I do?

If you are having difficulty pipetting the sample into the cartridge, a video demonstrating how to load a cartridge is available on our website. If the sample is having trouble wetting out the microfluidic channels, try adding a small amount of wetting agent or surfactant. We recommend using 0.1% to 1% of Tween (polysorbate-20) or bovine serum albumin (BSA). Another surfactant to consider is sodium dodecyl sulfate (SDS).

Q: How does Spectradyne's nCS1TM microfluidic resistive pulse sensing (MRPS) technology compare to NTA and DLS?

The fundamental difference between MRPS and NTA/DLS (nanoparticle tracking analysis/dynamic light scattering) is that MRPS is a direct, electrical measurement, whereas both NTA and DLS are indirect, optical measurements. Both NTA and DLS use light-scattering as the basis for their measurements, so the signal they measure is proportional to the 6th power of the particle size. This means that all measurements are heavily biased towards larger particle sizes. In DLS, this means that the reported mean size will always be higher than reality (except in very monodisperse populations). In NTA this can create a false peak in the distribution at lower sizes because the scattering from the larger particles obscures the scattering from the smaller ones (check out this technical brief, or this poster, or alternatively this poster).

In addition to the scatter signal measured by DLS and NTA being biased towards larger sizes, the scattering intensity is also reliant on optical contrast (difference in refractive index) between the particles and suspending media. For high optical contrast particles (gold nanoparticles, polystyrene beads, etc.) this does not cause any issue. However, for many biological nanoparticles (protein aggregates, extracellular vesicles, phages, etc.), the particles have little or no difference in optical contrast to the suspending media, which makes the scattering produced very small and, in some cases, non-existent. Finally, all light scattering systems must start with an assumption that all particles are spherical in shape.

In contrast, MRPS is an electrical measurement that has no dependence on either particle shape or material properties such as refractive index! Each particle is measured individually with no dependence upon the measurement of other particles in the sample.

A detailed discussion of different nanoparticle measurement technologies can be found on our technology page.

Q: Why are there so many bottles?

What a good question! The nCS1TM measures particles by flowing the analyte through a nanoconstriction (NC) and electrically sensing the volume of conductive buffer the particles displace within the NC. The measurement is facilitated by also flowing some analyte through a fluid resistor (FR) which is on the opposite side of the cartridge. We make positive and negative electrical contact with the analyte on the two sides of the cartridge via the running buffer, which is kept flowing to carry away waste analyte. Analyte that doesn't go through the FR and NC (which is most of it) flows from the analyte well to waste.

Now we can see why nCS1TM has five bottles: We independently provide buffer into and out of the two sides of the cartridge, which takes four bottles, and we have a fifth bottle for the analyte waste. Fluid flow though all parts of the cartridge is precisely controlled by adjusting the relative pressure of all six of the cartridge ports, in addition to providing a source and a dump for running buffer and analyte, the bottle volumes maintain these pressures. Since the analyte port is continuously controlled by our pressure controller, we don't need a bottle for that port.

Q: Where is the laser?

The nCS1TM uses an electrical, non-optical detection method to size and count each particle individually, one-by-one. Therefore, there are no lasers or any other optics in the instrument.

Software-related FAQs

Q: How do I update my mold calibration file?

Your cartridges are pre-calibrated at Spectradyne so you don't have to do it yourself. The mold calibration file contains factors that convert raw data into size and concentration information for particles in your sample.

There are two ways to update your calibration file to the latest version:

- If your computer is connected to the internet, just find and run the 'UpdateCal' app. This app is located in the Spectradyne Tools folder of the Windows Start menu and will automatically fetch the latest calibration file from Spectradyne's servers and put it in the correct location on your computer for you — all done!

- If your computer is not connected to the internet, email us for the latest cal file and instructions for where to put it on the computer. Since Spectradyne's support team is always there for you, this option is pretty easy too!

Q: How does the nCS1 measure and calculate concentration?

Spectradyne's nCS1 provides the most direct measurement of nanoparticle concentration available. Here's how:

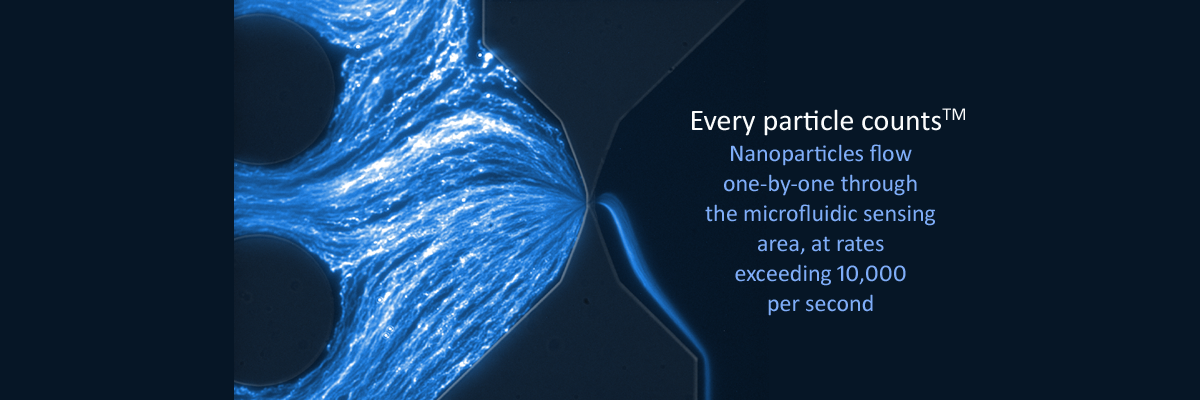

- Particles are detected one-by-one as they pass through the nanoscale sensing constriction inside the microfluidic cartridge. This can happen at rates as high as thousands of particles per second.

- Every time a particle is detected, the time it takes to pass through the constriction-its transit time-is measured.

- The transit time is essentially the time required for a volume of sample equal to the volume of the sensing constriction to flow through the detector.

- The average particle transit time for every acquisition is converted to volume flow rate of the sample using a cartridge-specific calibration factor that incorporates the geometry of the sensing constriction.

- Knowing the total volume of sample that has been measured, concentration on any given size range is calculated simply by dividing the number of particles detected on that range by the total volume.

Q: What is the meaning of the error bars shown in the concentration plots?

The nCS1TM counts and sizes individual particles, from which the concentration as a function of particle size is calculated. The uncertainty in the concentration, which is what the error bars represent, reflects the statistics of this counting process. If we assume that the measured data conform to a Poisson distribution, the counting error for a large number N of particles is equal N1/2. Large N thus gives a smaller fractional error than does small N; the general advice is thus to count more particles.

One detail is that as N becomes small, the error turns out to be asymmetric, with a larger positive uncertainty and a smaller negative uncertainty. For more explanation about this and other aspects of this topic, please refer to our technical brief on counting statistics.

Q: Why might I use "Background subtraction" and how does it improve my data?

Small particles generate small electrical signals, which are more easily masked by electrical noise than are larger particles. As a result, small particle events are more difficult to distinguish from electrical noise on an event-by-event basis using the instrument-standard peak parameters and filters.

To get more accurate concentration measurements close to the noise floor of a given cartridge, the electrical noise is estimated and eliminated using "background subtraction." Here's how it works: The raw signal measured by the nCS1TM is made up of broad-band electrical noise and discrete particle transit events, on top of a flat baseline. The electrical noise is symmetric above and below the baseline, but physical particle events only cause peaks on one side of the baseline (downward if you're looking at the raw data). The background subtraction method looks for peaks on both sides of the baseline — on the "real-particle" side, both real particle events and electrical noise false positive events are counted, while on the "non-particle" side, only electrical noise (false positive) events are counted. As the noise is symmetric above and below the baseline, the measurement from the non-particle side can be used to estimate the contribution of electrical noise to the particle size counts obtained from the particle side. The background subtraction method eliminates the contribution of electrical noise from your data, close to the noise floor, by subtracting the effective concentration of electrical noise events measured on the non-particle side.